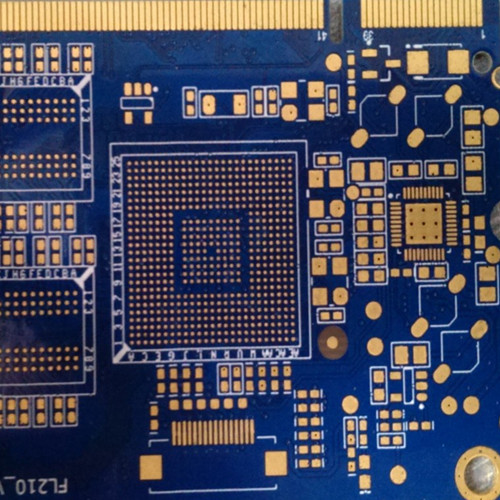

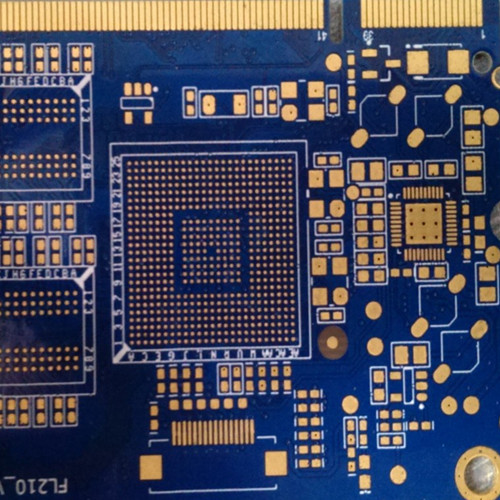

What are the advantages of gold, silver and other precious metals in PCB?

PCB If the surface needs to be welded, a part of the copper layer is required to be exposed for welding. These exposed copper layers are called pads, which are usually rectangular or circular in size and small in area. In the above article, we know that the copper used in PCB is easy to be oxidized, so the only copper exposed to the air is the copper on the welding disc after being painted with the welding resistance paint. If the copper on the welding plate is oxidized, it will not only be difficult to weld, but also increase the resistivity, seriously affecting the final product performance. So the engineers came up with all sorts of ways to protect the pads. For example, plating an inert metal gold, covering the surface with a layer of silver through a chemical process, or covering the copper layer with a special chemical film to prevent contact between the solder plate and the air.

From this point of view, the purpose of the process itself, whether gold or silver, is to prevent oxidation and protect the welding disc so that it can ensure the yield of the product in the subsequent welding process.

http://www.sharedpcb.com